AMI Innovation

The FlexNet® communication network securely transmits and receives customer usage data at over two times the power of competitive systems.

SafeGate Technology

Delivering OVER and UNDER pressure protection for all applications, SafeGate™ technology controls pressure with an added level of safety built in.

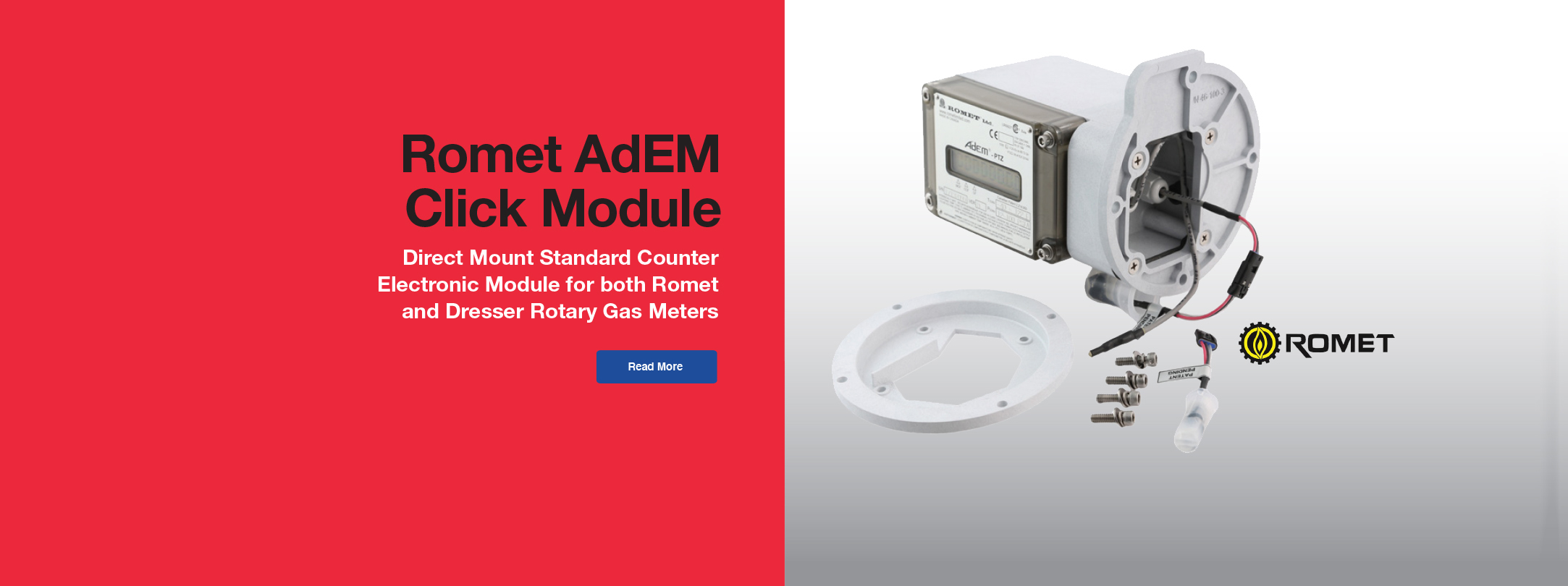

Romet AdEM Click

The next generation of direct mount electronic module rotary gas meters, the AdEM® Click has a high level of accuracy and customization.

Innovative Solutions Driven by Everyday Challenges

We provide natural gas measurement products, gas control products, and data acquisition products and services.